AMSOIL Break-In Oil: Designed for High-Performance and Racing Engines

AMSOIL Break-In Oil is a specialized SAE 30 oil designed to facilitate rapid and effective piston ring seating in newly assembled or rebuilt high-performance and racing engines. This oil is uniquely formulated without friction modifiers, prioritizing the establishment of proper ring sealing during the critical break-in period.

The formulation of AMSOIL Break-In Oil excludes friction modifiers, ensuring an optimal environment for piston ring seating without compromising the process with additional lubrication enhancements. Additionally, this oil contains zinc and phosphorus anti-wear additives that play a crucial role in safeguarding vital engine components during the initial break-in phase.

The inclusion of zinc and phosphorus anti-wear additives provides essential protection for cam lobes, lifters, and rockers at a time when wear rates are at their peak. Furthermore, the heightened film strength of AMSOIL Break-In Oil serves to shield rod and main bearings from potential damage, contributing to the overall longevity and reliability of high-performance engines.

AMSOIL Break-In Oil offers a tailored solution for new and rebuilt high-performance engines by prioritizing piston ring seating while providing essential protection to critical engine components during the break-in period. This specialized formulation underscores its suitability for demanding applications within racing and high-performance automotive environments. AMSOIL Break-In Oil is designed to increase compression, horsepower and torque for maximum engine performance.

Enhanced Protection for High-Performance Engines with AMSOIL Break-In Oil

High-performance and racing engines frequently utilize aftermarket components engineered to amplify torque and horsepower. However, this increased stress can lead to the rupture of the oil film responsible for averting detrimental metal-to-metal contact on rod and main bearings.

AMSOIL Break-In Oil: Enhancing Film Strength

To address this issue, AMSOIL Break-In Oil incorporates base oils that offer heightened film strength. This feature serves to safeguard bearings from wear, ensuring enhanced protection for high-performance engines subjected to elevated stress levels.

AMSOIL Break-In Oil is specifically formulated to counteract the potential damage caused by increased stress in high-performance and racing engines. By fortifying the oil film, it effectively shields rod and main bearings from wear, thereby prolonging engine longevity and performance.

AMSOIL Break-In Oil is formulated specifically for the break-in process of high-performance and racing engines that demand SAE 30 oil. Its primary function is to optimize compression, horsepower, and torque during the critical initial stages of engine operation.

Engine Break-In and Maintenance Guidelines

Engine break-in is a critical process that ensures proper seating of the piston rings and optimal performance of the engine. Following manufacturer’s recommendations and adhering to specific guidelines is essential for achieving maximum longevity and efficiency.

Follow Manufacturer’s Break-In Recommendations

- Prioritize following the engine builder’s or manufacturer’s recommended break-in procedures, if available.

- Ensure that the break-in period does not exceed 1,000 miles.

Understanding Oil Residue in Exhaust Ports

- Upon initial use, the exhaust ports may exhibit a significant area of oil residue due to the newness of the engine.

- As the piston rings gradually seat against the cylinder walls, less oil will pass through, leading to a reduction in oil residue area.

- A fully seated ring will form a tight seal against the cylinder walls, resulting in no evident oil residue.

Methods for Determining Ring Seating

- Other methods for confirming proper ring seating include conducting a leak-down test or monitoring horsepower measurements over time.

Variability in Break-In Duration

- It is important to note that break-in duration may vary between different engines due to their unique characteristics and specifications.

Post-Break-In Maintenance

- After completing the break-in period, it is recommended to drain and refill the engine with an AMSOIL high-performance synthetic oil that meets builder or manufacturer specifications.

Adhering to precise break-in guidelines and conducting post-break-in maintenance with suitable synthetic oils are crucial steps for ensuring optimal performance and longevity of an engine.

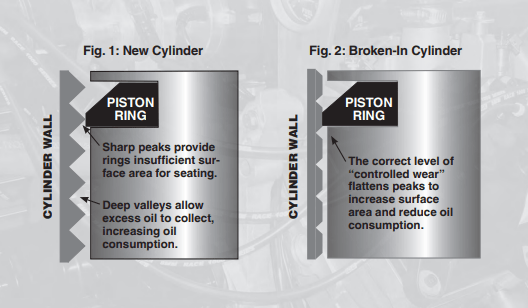

Engine Break-In Procedure for Ring Seating and Wear Control

Engine break-in aims to effectively seat the rings against the cylinder wall. This process enhances compression, maximizes horsepower, minimizes oil consumption, and prevents the penetration of hot combustion gases into the crankcase. Achieving these objectives requires careful management of oil properties to facilitate controlled wear between the cylinder wall ring interface while ensuring adequate wear protection for other vital engine components.

Key Objectives of Engine Break-In

The primary goals of engine break-in are as follows:

- Seating rings against the cylinder wall.

- Increasing compression to achieve maximum horsepower.

- Reducing oil consumption.

- Preventing hot combustion gases from entering the crankcase.

Oil Management for Controlled Wear

To accomplish effective ring seating and controlled wear during engine break-in, it is essential to manage the oil properties in a manner that:

- Allows controlled wear between the cylinder wall ring interface.

- Maintains wear protection for critical engine parts other than the rings.

Proper execution of engine break-in procedures is crucial for achieving optimal performance and longevity of internal combustion engines. By prioritizing ring seating and managing oil properties to facilitate controlled wear, engine break-in can successfully enhance compression, minimize oil consumption, and safeguard critical engine components from excessive wear during initial operation.

Note: The above text maintains content accuracy while presenting it in a different format with an emphasis on technical precision and clarity. The impact of insufficient break-in on the cylinder wall surface can lead to various issues affecting the functionality and longevity of an engine. This article aims to explore the consequences of inadequate break-in procedures on the cylinder wall surface.

Insufficient Break-In and Cylinder Wall Surface

Insufficient break-in procedures can result in irregularities on the cylinder wall surface, which have significant effects:

- Peaks Formation:

Inadequate break-in can lead to the formation of peaks on the cylinder wall surface. These peaks hinder proper seating of the rings, impacting engine performance. - Valleys Formation:

Simultaneously, insufficient break-in may create deeper valleys on the cylinder wall surface. These valleys promote excessive oil accumulation during combustion, leading to increased oil consumption.

Cylinder Glazing Due to Wear

Excessive wear caused by insufficient break-in can lead to cylinder glazing, characterized by:

- Peaks Rolling Over:

Excessive wear causes peaks to roll over into the valleys on the cylinder wall surface. This process impedes proper oil collection and lubrication, further impacting engine performance.

In conclusion, it is imperative to prioritize a comprehensive and adequate break-in procedure for engines. Addressing irregularities in the cylinder wall surface due to insufficient break-in is essential for optimizing engine performance and longevity.

The friction-modifier-free formula of AMSOIL Break-In Oil facilitates the partial flattening of sharp peaks on newly honed cylinder walls. This process increases the surface area for rings to seat against, enabling the formation of a dynamic seal. As a result, compression, horsepower, and torque are enhanced.